JYM cares about the quality of the tools, which is to deliver strict standards and near-perfect products for your brand

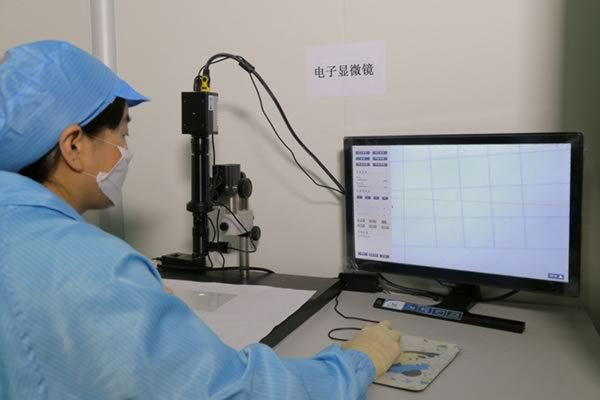

Incoming Quality Check - IQC

Must be conducted for any incoming material before it goes into mass production process.

Pre-production Quality Check - PPQC

Must be conducted by production manager, quality manager and sales people, after all approved, then it can go through mass production process. Meanwhile, sales people will send PPQCR (Pre-production Quality Check Report) to customer.

In Process Quality Check - IPQC

Must be conducted by quality management department and production departmen for each production process randomly to make sure the quality is as good as it is. IPQCR (In Process Quality Check Report) will be sent upon request.

Spot checks - AQL

In the production process, JYM conducts product sampling and testing to ensure that the product delivery is delivered to a consistently high standard

Out Going Quality Check - FQC

Must be conducted by production manager, quality manager and sales people, after all approved, then it can go.

Production inspection - OQC

For delivery standards, JYM treats each product as strictly as its own brand