You’ve Got the Production Team in China

JYM also provides a strong OEM service that can build your brand. The extensive options on your customized EC mirror/make up mirror, our certified production facilities and the equipments and experience our team have, can set you apart from your target market.

Count on our ensure state-of-the-art machinery and we can accomplish your order of EC mirror with a fast lead-time without compromising on quality.

Glass Cutting Service

JYM Glass is equipped with 19 cutter sets to satisfy production needs that require different processing techniques. Your glass and lenses will be cut into a variety of shapes, including round, rectangle, polygon, oval and more.

Glass Coating Service

The glass coating process is carried out in a vacuum environment and is the process whereby a single or multi-layer functional film is applied to one or two glass surfaces. According to different glass characteristics and different function requirements, we offer a diverse array of coating films, including reflective film, semi-reflective film, transparent film, enhanced transparent film, anti-reflective film, and colored glass film.

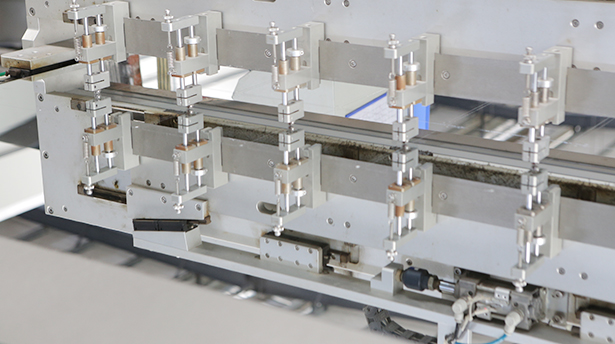

Glass Polishing and Edging Service

According to client provided drawings or detailed sample requirements, our design department will analyze and discuss options before beginning any glass project.

We own and operate two Japanese glass edging production lines to perform the first cutting and edging steps on raw glass pieces. These lines are capable of processing glass with a thickness range of 0.2 to 4mm.

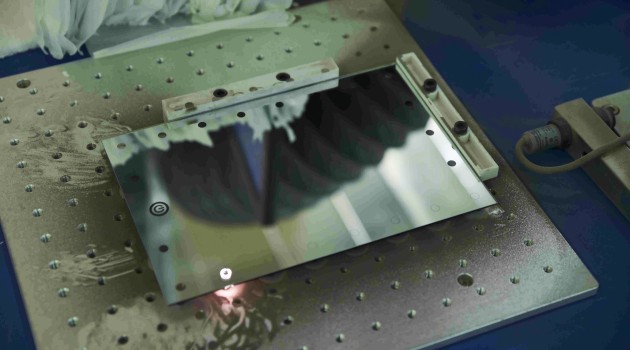

Make up mirror laser engraving services

LED cosmetic mirrors engrave any shape and pattern, and control touch quality

Glass Bending Cutting Service

JYM produces high-magnification lenses and supports cutting with curved lenses

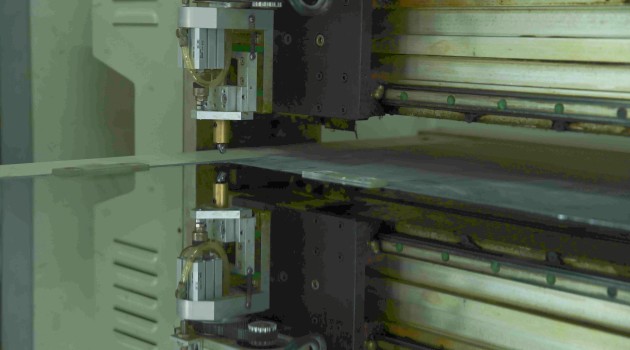

CNC microtome

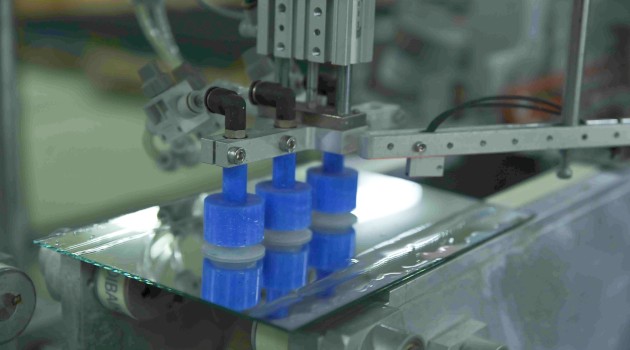

JYM has been pursuing automated production, and delivering high-quality products is the growth milestone of the company's vitality

Large unloading machinery

The assistance of machinery often improves production efficiency and product loss

Glass/Mirror ITO Service

Our film coating services are widely used in the production of cosmetic mirrors, reflective mirrors, crafted glass, LCD, touchscreen and specialty glass products.

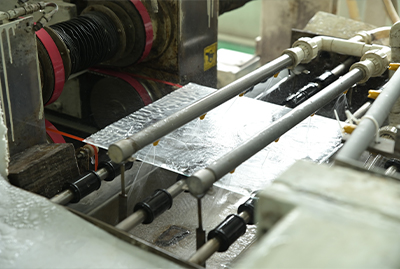

Glass/Mirror Bending Service

In addition to the aforementioned glass processing services, JYM Glass also provides hot bending processing. Compared to flat surface glass products, glass walls and furniture with a curved surface offers an exclusive, innovative look. During the manufacturing process, the glass is heated and bent under high temperatures into the required shape, then cooled. All processing steps are done via computer control, ensuring an ultra-high accuracy.